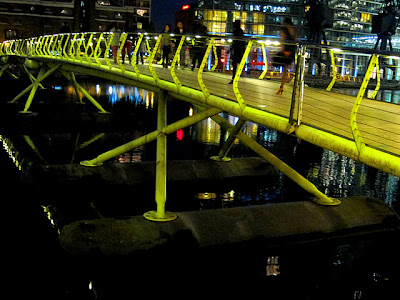

At night the lights illuminate the bridge with yellow dots

and bars of light. Reflections of light glaze the surface of the bridges

walkway and denounce the actual structure of the bridge. Movement of the bridge

on the water is enhanced by the intensity of the light, and peoples movement

blocks the light intermittently giving the effect of transfer from one side to

the other. Activity feels like it is increased at night.

Friday, 28 October 2011

Thursday, 27 October 2011

structure

Weight distribution and structural forces

Displacement

The bridge stays steady due to the massive displacement of

the pontoons

- 1. Tapered span decking structure supported by four sets of 2 pontoons

- 2. Light tension piles support the pontoons from the river bed

- 3. The span of the bridge has longitudinal spine support running the length of the two main side sections

- 4. The diagonal steel struts yhat provide the main support of the bridge decking structure rest upon the tubular steel framework legs.

- 5. This type of loading alleviates any downforce that would act upon the sides of the canal which was conditional of winning the design competition

Walkway decking

The bridge is made up of two main curved sections and a

straight middle section that can be hinged upwards to allow for boats to pass. The

cantilevered lift is controlled by the harbourmaster. This section is raised by

hydrolic rams.

15cm wide aluminium box section plates make up the

non slip surfacing

Railings

There is 34 sets of vertical railings that are strung between

with stainless steel cable. This is reminiscent of nautical fittings on boats .

Materials used

1. Bridge decking:

box section aluminium extruded

2. Tubular support

structure: splayed tubular steel 10mm thick

3. Pontoon (floats):

rolled steel with end caps (polystyrene foam) aids buoyancy

4. Railings:

verticals are steel plate top hand rails are tubular staircases

5. Cables:

6. Span substructure:

7. Lights:

flouresent light tubes contained in polycarbonate boxes

Structure

From the water up....

- · Pilings

- · Floats (pontoons)

- · Supporting crossmembers

- · Bridge span stuructural members

- · Bridge decking

- · Parapets, railings, banisters, lighting and drainage.

- Weight distribution and structural forces

Displacement

The bridge stays steady due to the massive displacement of

the pontoons

Movement of the bridge

As pedestrians stroll across the bridge the vibrations cause

a shifting and canter effect. the vibrations increase with the human traffic. At

the ends of the bridge there are small caster wheels to allow for this

movement. One way to measure this movement is to log the slide of the wheels .

the rubber coating on the wheels has worn due to this.

Construction

- Construction of the bridge was contracted by Littlehampton welding.

- · Pontoons are made from rolled steel ...foam filled

- · Main supporting cross-members were made from welded steel pipe bolt/plate mounted to the pontoons

- · The bridge is made in sections

- · Diagonal members are made from welded steel

Wednesday, 26 October 2011

Surveying

Future Systems' lime-green steel footbridge streaks across the dock of West India Quay, floating on its cylindrical pontoons like an insect on a pond.

The bridge has a low-rise profile and a tapering plan, which emphasises the perspective viewpoint of pedestrians. At night, the handrails light up.

The deck is supported on a series of X-shaped tubular steel struts linked to a central under-spine. The struts have circular foot plates, which are bolted to the pontoons. The span of the bridge is 80m.

Architect: Future Systems

Services engineer: Rendel Palmer & Tritton

Quantity surveyor: Bucknall Austin

Contractor: Littlehampton Welding

This video shows the movement of the bridge as the bridge is not build into the dock. Through observation we can see that on either side of the bridge we can see wheels. As you can clearly see here in this video that the bridge moves down slightly as people walk by.

Subscribe to:

Comments (Atom)